Industrial equipment monitoring (IEM) allows you to monitor your equipment to create transparency leading to greater efficiency and reliable service for your customers. Use the Losant Internet of Things (IoT) Enterprise Platform as your cloud foundation to collect, organize, report, and respond to data from new and existing systems. One of the most significant benefits is the ability to build multi-tenant applications to extend the advantages and create more value for your customers.

Industrial Equipment Monitoring: Create More Value for Customers

Better Track Your Equipment With Losant's IoT Platform

Compressor

Our customers can store and analyze data from vibration, voltage, temperature or pressure sensors to understand trends and create predictive maintenance solutions based on compressor activity.

Pump

Our customers can combine sensors with gateways for connectivity, to gather data from pump machine controllers in difficult to access or remote locations.

Engine

Our customers can use edge computing to read engine controller data about the condition of its components. Users gather data, display critical information on a dashboard and create incident reports or alerts if a condition requires attention.

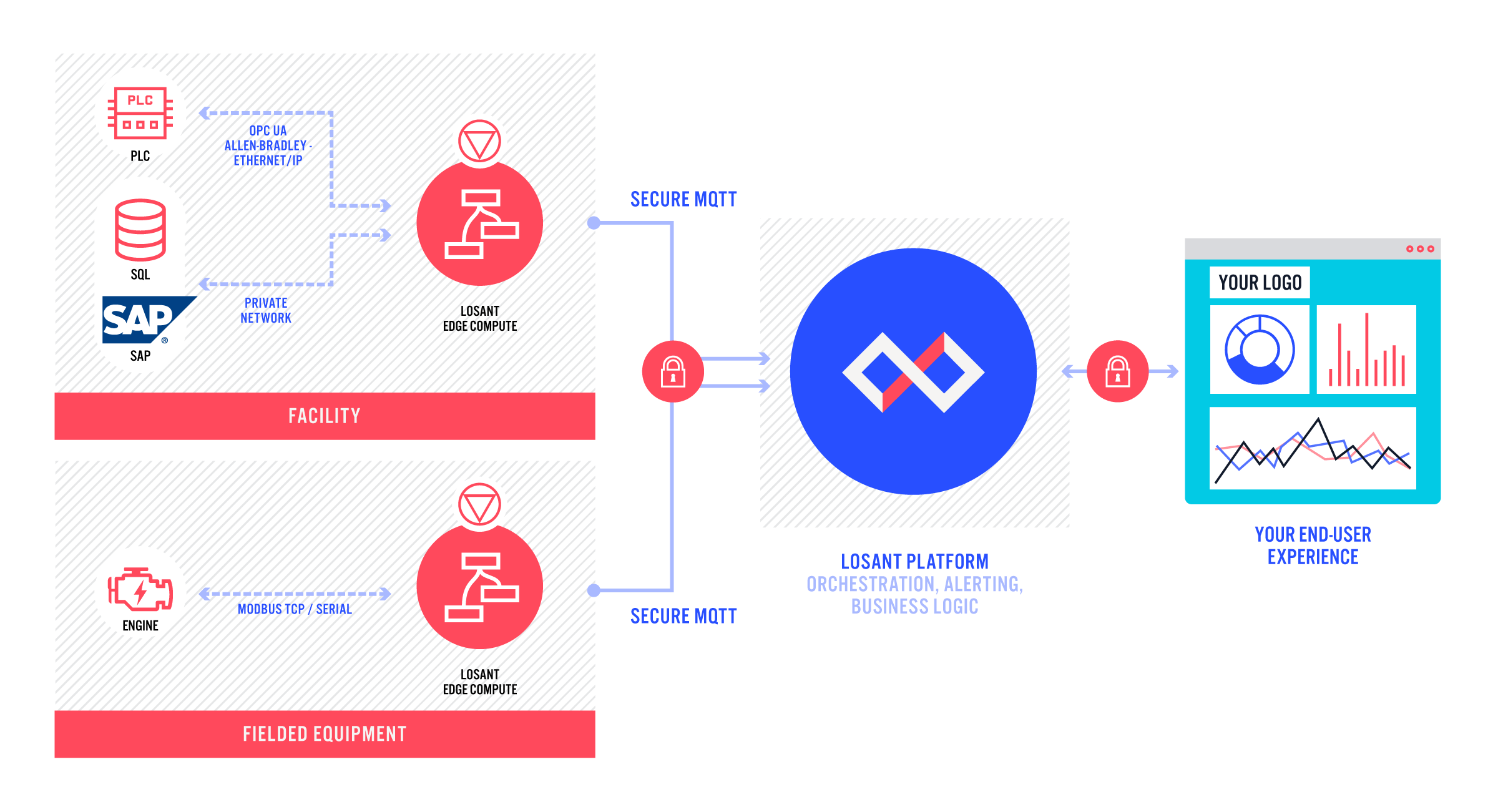

Edge Compute Architecture

Edge computing uses connected and non-internet connected devices — anything from existing PLCs, motion sensors, and gateways — to process data near where it is collected. So, instead of sending all of the data to the cloud, edge computing can process data and send a smaller selected set, accelerating the delivery of data.

Benefits of IEM: Improve Productivity With Less Time and Money

Cost Control

Proactively respond to abnormal equipment conditions instead of complete system breakdowns. Streamline repair efforts to avoid unnecessary scheduled maintenance.

Increased Productivity

Optimize field support technicians by reviewing asset data on a dashboard before deconstructing equipment. Connect manuals and inventory systems to review repair instructions or immediately order parts.

Exceptional Service

Provide customers with access to instant supply chain information and give them the ability to make better business decisions.

Use Losant’s IEM Application Template to Harness the Power of IoT

The Industrial Equipment Monitor Application Template is designed for OEMs, telecoms, or other solution providers and offers customers a way to monitor equipment and gain instant access to equipment telemetry data. Learn best practices, see an application architecture example, and learn how to bring together key Losant features to provide more functionality for your application during this Deeper Dive on-demand webinar.

Why Losant?

Make faster and better-informed decisions with visibility to unified information from disparate devices, machines, and data sources.

Losant Accelerates the Creation of IoT Solutions |

|---|

|