Learn how your enterprise can increase its competitive advantage with industrial IoT (IIoT). Explore recurring revenue opportunities using IoT data insights. Learn how other organizations used industrial IoT and multi-tenant applications to offer new value to customers through the introduction of industrial equipment monitoring, condition-based maintenance, and asset

.jpg)

What Will I Get?

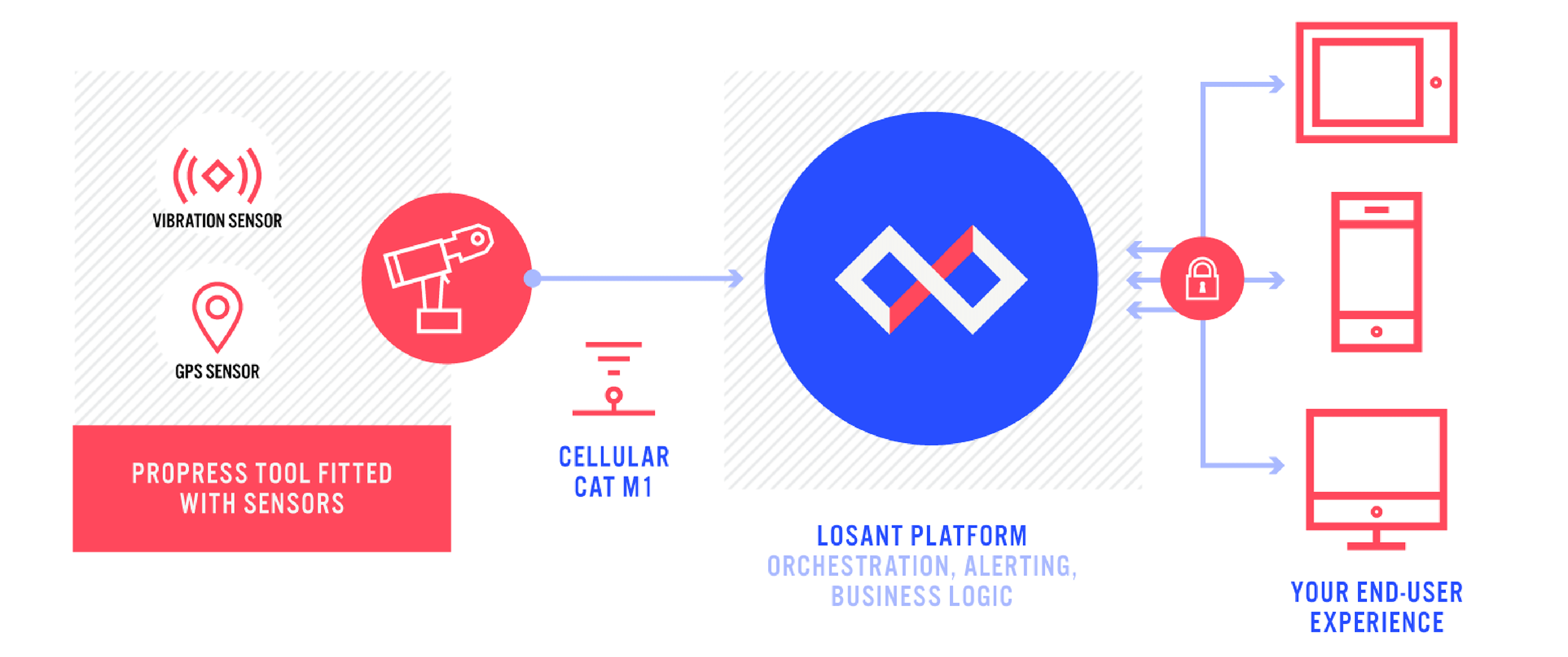

- Diagrams to help you understand the IoT architecture behind IoT solutions created for customers

- Stories behind real-world industrial IoT solutions

- Tips on how to choose IoT hardware and a connectivity network for your environment

- Questions to ask your team of internal stakeholders about how to get started

Look inside

the Guide

Expand Offerings, Build Relationships,

and Secure the Future by Integrating IoT

Since 2000, over 50 percent of companies in the Fortune 500 have either gone bankrupt, been acquired or ceased to exist as a result of digital disruption.

Harvard Business Review

This data represents only a portion of enterprises who couldn’t respond appropriately to industry changes and new customer needs. However, companies that have survived for the last two decades have found ways to successfully integrate technology for process optimization AND evolve their offerings to meet the new demands of the businesses and the connected customers they serve.

The Solution

The IoT hardware company created a proof of concept using a small 3-D printed box which contained a battery-powered vibration sensor and a GPS sensor. The box was affixed to the tool with screws and the sensors sent data to the IoT platform using a cellular Cat M1 network.

The Value

After the initial investment of the IoT solution balances out, this manufacturer stands to gain revenue from a monthly subscription fee for helping its customers who own businesses track location and usage of its valuable assets.

Inside an Industrial IoT Solution

In The Losant Guide to Business Innovation and Expansion with Industrial IoT, you’ll see exactly how an industrial plumbing company used Losant to monitor equipment and turn the location data into an end-user experience.

Questions to Ask

Here are the questions you should ask when trying to identify what kind of connected solution will bring the most value to your customer using data from IoT.

What kind of problem can you solve for your customer to provide additional value?

COMMON EXAMPLES INCLUDE

- Supply chain transparency

- Industrial equipment monitoring

- See the complete list in the guide

Where does data already exist in your customer’s environment?

Common Examples Include

- Machine controllers

- Equipment

- WiFi network

- See the complete list in the guide

Which data will provide the answers your customer needs to add value to their business?

Common Examples Include

- Motion detection

- Geolocation

- Air quality/VOCs

- See the complete list in the guide

Which kind of experience will best suit your customer or their customers?

Common Examples Include

- Mobile application

- Unique user IoT interface

- Storage for data analysis

- See the complete list in the guide

How Should My Organization Select Hardware for a Connected Solution?

Choosing the correct hardware can often be the most complicated part of developing an IoT solution. Things like availability, cost, intended environment, battery life, and connectivity options all have to be factored together when making hardware choices.

Environment

An IoT solution that provides data about varying machine component conditions can help customers monitor conditions and reduce maintenance costs with condition-based maintenance.

Connectivity

An IoT solution designed for asset tracking and data integration can benefit customers in a range of industries.

Data Access

An IoT solution that grants access to machine data can help an enterprise remotely measure, monitor, and manage production from anywhere.

Gateways

For industrial equipment monitoring solutions, the hardware choice is often limited to choosing a gateway that can bridge the gap between your equipment’s local environment and your IoT cloud platform.

Sensors

If your IoT solution requires the introduction of new sensors to generate the required data, finding off-the-shelf vendors is usually the most successful approach.

Custom

Custom hardware is for organizations where there is no off-the-shelf option to meet their needs. It typically comes with a significant up-front cost, but the per-unit cost can sometimes be cheaper than off-the-shelf when operating at scale.

CASE STUDY: Asset Tracking & Industrial

Equipment Monitoring

The Opportunity

An industrial plumbing equipment manufacturer has recently learned that business owners who buy their products would like to integrate location and usage tracking information into their equipment to help them better manage resources. Plumbing equipment often gets lost, left behind or mismanaged. Not knowing location and condition of equipment leads to a lack of insight into day-to-day operations. If a customer’s work order is delayed, bad reviews are reported and business slows. Access to location data can give insight into what’s going on to resolve problems for business owners.

The Process

The product manager from the plumbing equipment manufacturer researched the IoT stack to understand how this solution could be built. Web research yielded a systems integrator who introduced the team to a cellular connectivity group, and an IoT platform who had completed a similar project with a case study on its website. The IoT platform provider introduced the company to the hardware partners who could provide the necessary sensors.