If you’re an OEM and pursuing the Internet of Things, one of your biggest opportunities is to offer an IoT service that extends the value of the equipment you sell. A remote monitoring service gives your customers instant visibility into the performance and health of their equipment while simultaneously providing you a new recurring revenue model.

Building an IoT service for existing equipment is easier than you may realize. Most industrial equipment already has a controller with a rich source of telemetry data. This article will describe how to tap into that source of data to build an industrial equipment monitoring IoT service that you can offer for your customers.

Step 1: Understanding Your Equipment’s Controller

Over the years Losant has helped a number of OEMs deliver IoT services. In all cases, the first hurdle is gaining access to your controller’s data. Nearly ever controller exposes some form of communication. It could be Modbus, CAN bus, OPC UA, or any number of other protocols.

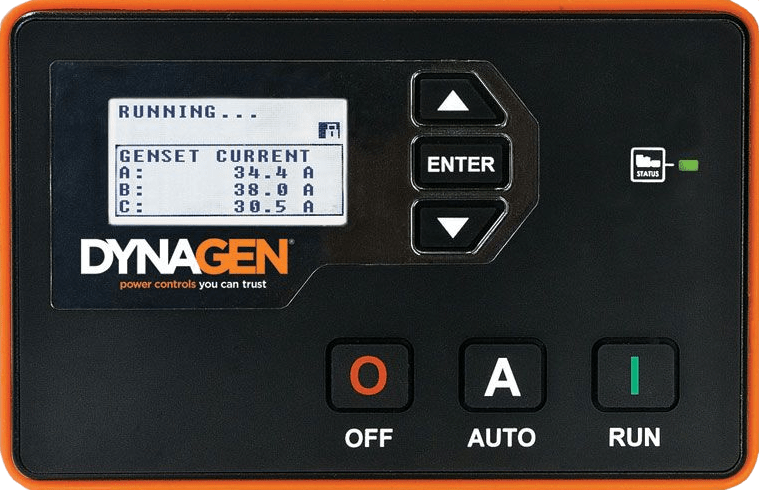

For example, the TOUGH Series® TG410 Generator Controller from Dynagen supports both CAN bus and Modbus.

Your equipment may be using a third-party controller (e.g. Dynagen) or it may be something you’ve developed in house. In either case, the first step is to contact the appropriate representative and get access to the communication protocol for your controller.

Step 2: Choose your IoT Platform Provider

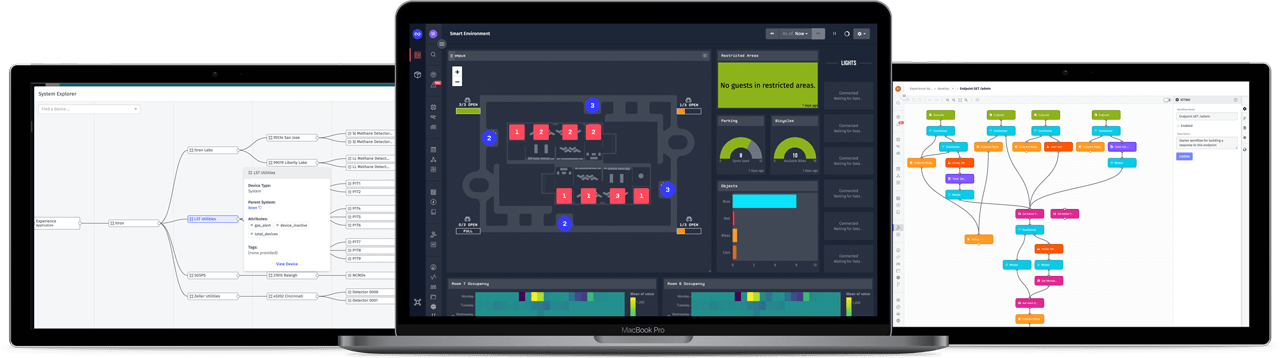

Delivering an IoT service requires a large amount of platform technology that sits underneath what your customers experience. This includes, edge computing, data ingestion, data warehousing, real-time stream processing, batch analytics, visualizations, and finally an end-user experience tailored to your brand and customers.

It’s called a platform because it’s an application-agnostic base of technology not specifically tailored for any single use case. An IoT platform provides the foundational technology that underpins nearly all IoT products and services.

It’s a “buy vs. build” decision and the reason I recommend buying an IoT platform is because building this technology is a significant cost and time investment that does not directly add any value to your customers. IoT platform providers also bring a unique skill set to your organization when it comes to developing secure and scalable cloud services.

Step 3: Build Your IoT Proof of Concept

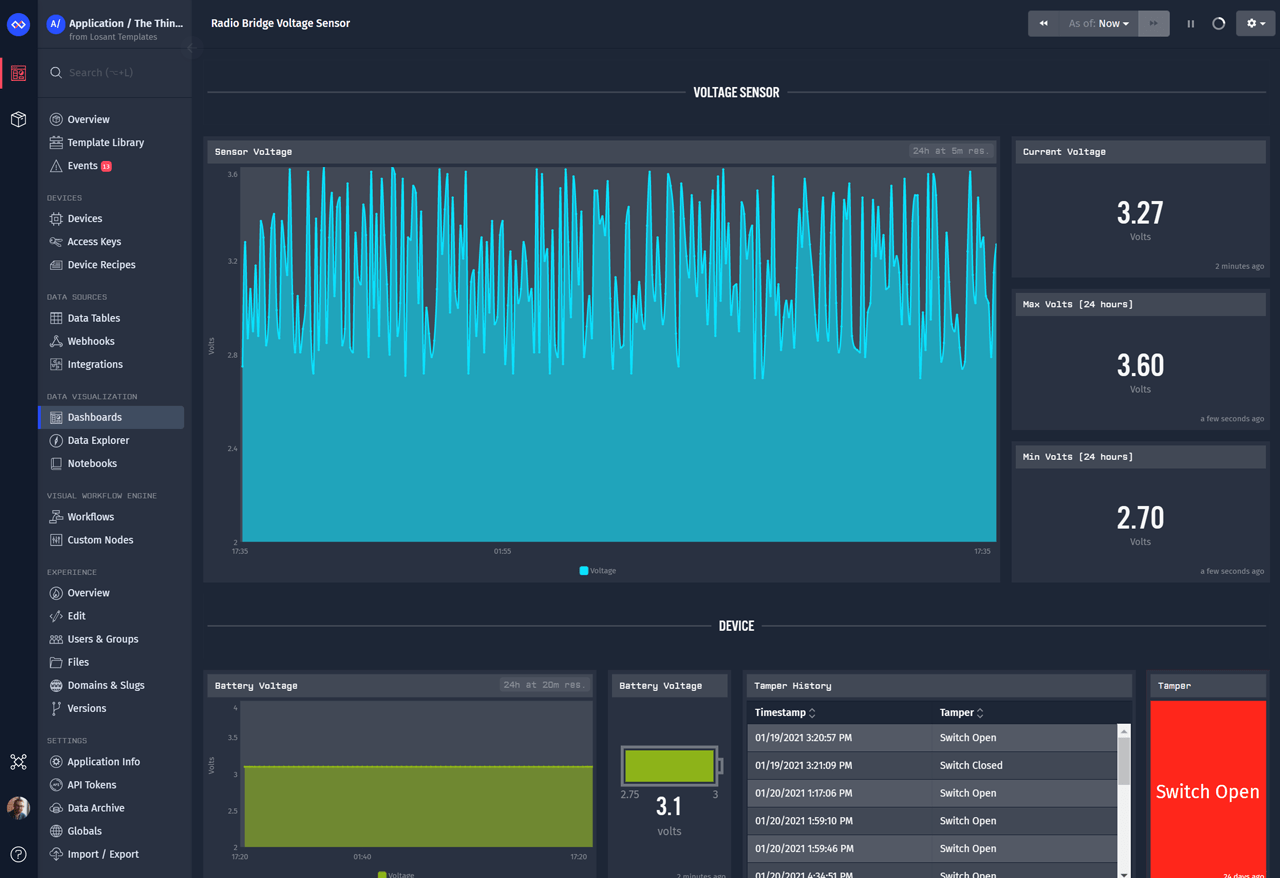

Now that you know how to communicate with you controller and you’ve selected an IoT platform, the next step is to determine whether or not your controller and platform deliver what you require.

For example, a valuable feature in a remote monitoring service is to send a real-time alert to the customer whenever a fault is detected. To accomplish this, the controller must expose fault information over its communication channels and the IoT platform must support sending alerts to your end-users.

The purpose of a Proof of Concept (PoC) is to build a very simple version of your IoT service to prove that it can deliver your critical requirements. Performing a PoC reduces risk by allowing you to “fail fast”. You don’t want to be put in a position where you’ve been building a product for months only to discover a critical component is missing late in development.

The most important part of a PoC is defining very specific goals. Each goal should be a fundamental requirement that must be met before your project will move forward. For example, the goals in the real-time alerting example from above could be something like the following:

- Fault codes are retrieved and reported to the cloud within 30 seconds of when they occur.

- When a fault code is received by the cloud, an SMS alert is sent to the customer that owns the device.

Each goal should be thought of as an item in a checklist. If every item is checked at the end of the PoC, you have greater confidence that the technology will deliver the IoT service your customers require.

Step 4: Choose your IoT Gateway and Connectivity Providers

In most cases, your equipment’s controller does not have the ability to directly communicate with the cloud or your IoT platform. We find retrofitting the equipment with an inexpensive Linux gateway to be a successful approach to accomplish this. The gateway acts as a bridge between your equipment’s controller and your IoT platform.

Most off-the-shelf gateways support a variety of connectivity options depending on how your customers deploy your equipment. If your equipment is in the field, cellular connectivity is a good option. If your equipment is installed indoors, WiFi or Ethernet may be all that’s required.

You can validate your gateway and connectivity choices as part of your PoC, but it’s not required. The decision parameters are usually straightforward and your PoC will highlight the technical requirements that will help guide your choices.

The most important factor when choosing a gateway is whether or not it will run your edge computing technology stack. Losant distributes its Edge Agent as a Docker image, so the deciding factor when using Losant as your IoT platform is whether or not the gateway supports Docker.

Step 5: Develop Your Customer-Facing IoT Service

Steps 1-4 are about building your specific technical foundation. Once your foundation is in place, you can begin building the IoT service that delivers value to your customers.

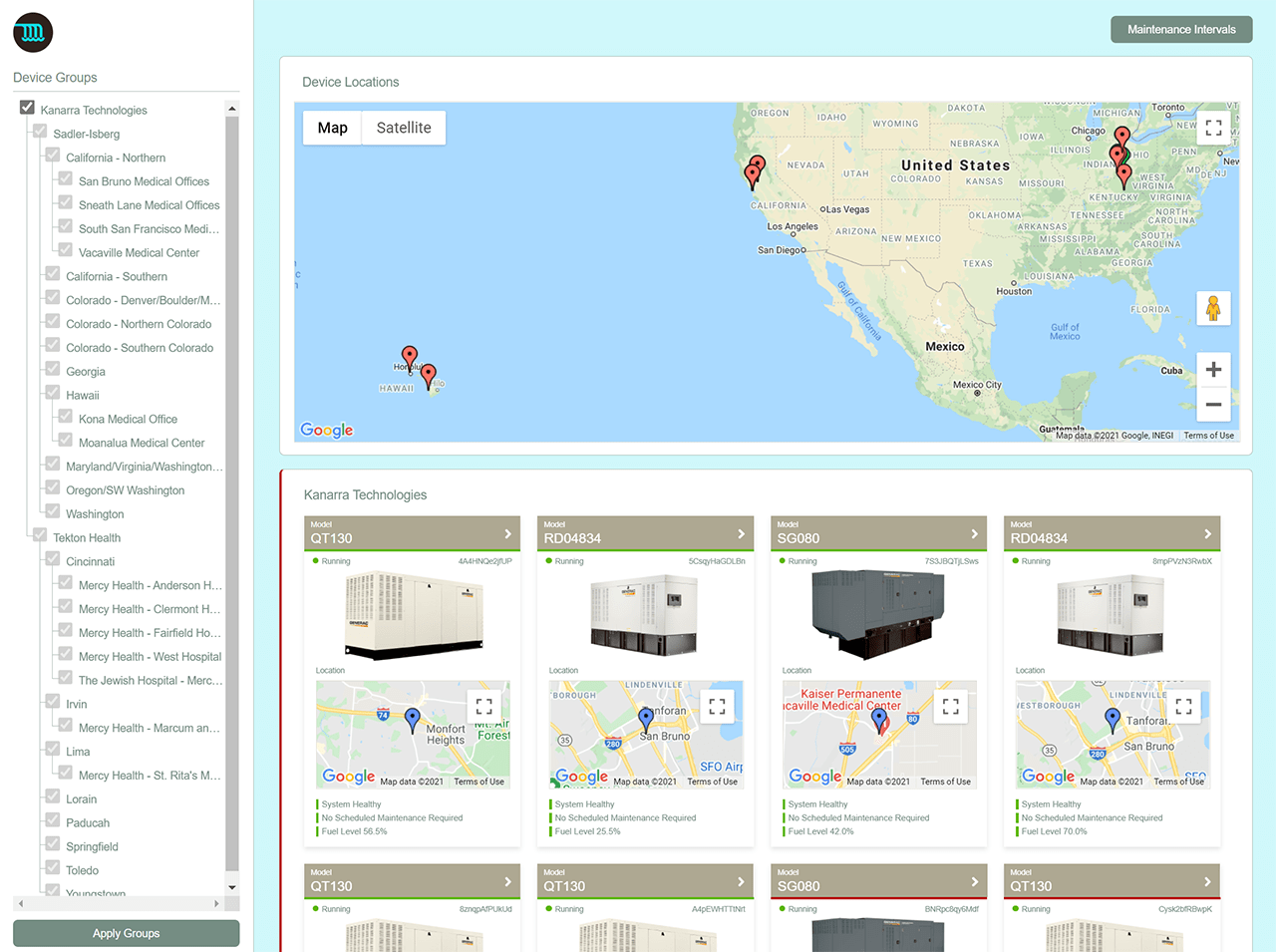

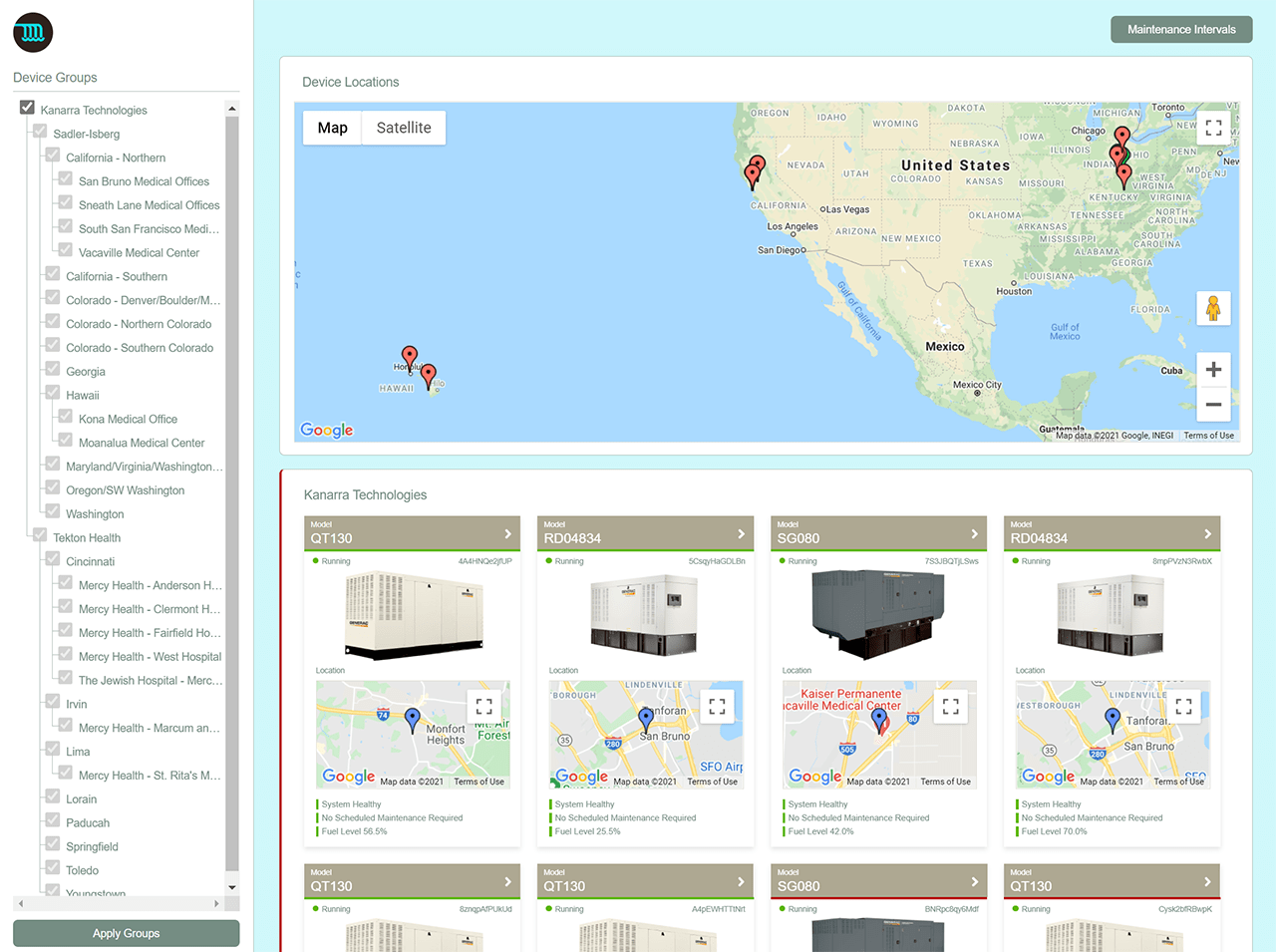

The most important aspect of a customer-facing IoT service is the concept of multi-tenancy. As the OEM, you have many customers (i.e. tenants), and even though every customer logs in to the same service, they should only see and have access to the equipment they own.

The user interface (i.e. experience) that you develop is highly dependent on your specific requirements and the equipment you sell. Most industrial equipment monitoring experiences will include, at a minimum, user authentication, data visualization, and SMS/email alerting.

Building your tailored end-user experience will be the most time-consuming part of the entire development process. Due to the highly-customized and domain-specific nature of a customer-facing application, there aren’t many tricks or shortcuts available when it comes to building the user interface. Organizations discover quickly that out-of-the-box dashboards, while they do work great for internally-facing applications, do not provide the flexibility required to deliver highly-customized user interfaces for their customers.

To deliver a tailored end-user experience, traditional web development is required. Having a web developer on your team, or outsourcing to a web development firm, has proven to be a successful approach.

Develop your IoT Service on the Losant Enterprise IoT Platform

Losant provides the complete edge and cloud software foundation to build and scale compelling IoT solutions for your customers.

Losant’s End-User Experiences functionality embraces the need for UI customization while providing a number of high-productivity features to reduce overall development time. This includes user authentication and multi-tenancy, direct integration with devices and data, and a unique Visual Workflow Engine to quickly develop all aspects of your application’s business logic.

Losant’s industry-leading IoT platform has been used as the foundation for IoT products and services across a variety of organizations - from startups to Fortune 100 enterprises.

Our team is standing by to answer any questions you have. Please contact us to learn how Losant can help your organization deliver compelling IoT services for your customers.