The path from IoT project to IoT ROI has become more clear for enterprises. Data storage costs continue to decline, and as 5G emerges, connectivity options will optimize and expand. Computing is more efficient than ever before. Generating revenue with IoT has become easier to navigate as well. More organizations have begun to provide digital services to complement products.

In a recent McKinsey study it was found that those enterprises that have begun digital transformations, or what the article refers to as, IoT leaders, anticipate that their IoT use cases will boost their gross profits by 13 percent over the next three years, which is three times as much as IoT laggards, or those who have not begun. It won’t be long before every company is harnessing the power of IoT.

"The IoT will continue to deliver new opportunities for digital business innovation for the next decade, many of which will be enabled by new or improved technologies. CIOs who master innovative IoT trends have the opportunity to lead digital innovation in their business."

Nick Jones, Gartner Vice President and Distinguished Analyst

It’s been estimated that 94 percent of enterprises will use IoT by the end of 2021. If your organization has yet to make a move or is stuck in a stalled project, here are the steps your team can follow to move IoT projects into production.

1. Select an IoT Project Aligned to Company Goals

To put it simply, IoT data enables cost savings or revenue generation. Chances are, your organization has a goal attached to one of those initiatives. To identify the appropriate opportunity, engage your sales and customer support teams to discover common issues. Conduct user surveys to learn where the opportunity areas are and learn which problems can be solved with data. Align how the results are tied to value for the entire organization.

One great example of a company using IoT to advance initiatives is UPS. There’s tough competition in the courier industry. Each vendor is competing to be the fastest and most efficient with the leanest operation. To remain competitive, UPS began gathering data from vehicle sensors on its delivery trucks, GPS tracking equipment, and drivers’ handheld devices to understand where efficiencies could be gained. This data, combined with a committed investment into operational technology, resulted in the development of ORION, or UPS’ On-Road Integrated Optimization and Navigation. Today, the ORION algorithm uses the data captured to provide the best routes for drivers and continues to learn as it goes, optimizing more than 55,000 routes in North America before drivers leave UPS facilities. Juan Perez, Chief Information and Engineering Officer for UPS, has explained that UPS has saved more than $400 million with this technology.

2. Evaluate and Select IoT Partners

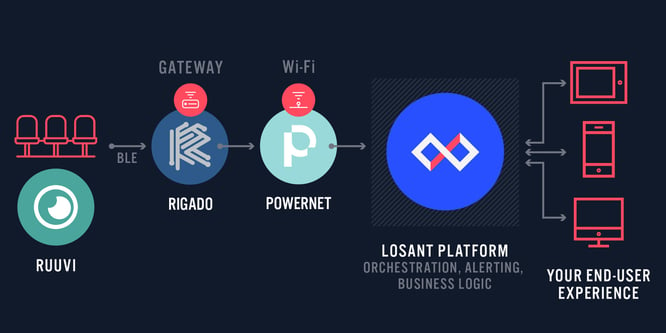

The IoT landscape is crowded and your IoT project will undoubtedly require more than one partner. The IoT landscape, also known as the IoT ecosystem, refers to the network of IoT suppliers (hardware, connectivity, software platforms, system integrators, and data analytics) whose combined services help enterprises create complete IoT solutions. Nearly every IoT solution involves the same four components: devices, connectivity, a platform, and an application. While your internal team may be very talented, you can reduce costs and time to market with external IoT expertise. Select partners based on the problem you identified as it is related to each supplier’s industry expertise.

|

Need IoT connectivity guidance? Download our one-pager to understand the options. (479 KB) |

3. Conduct a Proof of Concept, or Proof of Value

A low-risk proof of concept (PoC) is the best way to introduce IoT to any organization. The purpose of a PoC is to experiment with a solution in your environment, collect data, and evaluate performance within a set timeline on a set budget. A PoC allows your team to commit to a specific investment of time, budget, and resources. It also requires your team to define goals and success metrics. Results of the proof of concept will help the IoT project team make decisions about how to select partners, improve an IoT solution design, and learn if the IoT platform is a good fit. If data collected in the PoC helps teams make better decisions internally or for customers, the project can be a model for other projects in other departments. Discover more about Losant’s PoC process, or speak to an expert about beginning a PoC in your organization.

4. Launch a Pilot, if Applicable

The purpose of a pilot, or a small-scale rollout, is to test a solution with a small group of users in the actual environment. After the proof of concept, identify a small portion of the target audience with which to share your solution. That audience could be a small subset of the target market in a region or one internal department that can use an application before an entire organization receives access. We encourage our clients to start with a pilot to eliminate any issues with hardware, connectivity, or operations in a limited group. Pilots are also very valuable for customer-facing IoT solutions because it enables customers to contribute feedback in time for your organization to make enhancements or modifications. Many mobile organizations, including Verizon and T-Mobile, use pilot cities to test new connectivity options. This small scale run helps teams create a set of procedures for people in the beta group of testers to follow to identify any issues. Ensure an official feedback mechanism is in place, then optimize production performance according to pilot results.

5. Move Confidently Into IoT Production

IoT solutions require a combination of engineering disciplines including system architecture, electrical, computer, software development, network/connectivity, user experience, as well as project management know-how. To produce and install an IoT solution, often more than one external partner is required as well as successful collaboration with an enterprise’s internal departments.

For example, to operate a smart stadium deployment for seat utilization information, an organization needs physical hardware sensors discreetly installed. In some use cases, hardware has to be custom designed and produced. A stadium may also require increased connectivity, which may mean additional cabling, antennae or access points. It will also need an application developed that can accept data from those sensors. Additionally, a supplier will need to build an interface that can help people easily analyze the data and make decisions based on what is learned.

Over the last two years, an increase in IoT endpoints shows that though often complex, IoT solutions are being completed at an increasing rate. We recommend creating a complete production plan after executing a successful proof of concept and pilot that includes the following:

- Requirements

- Timing

- Budget

- Device Inventory

Additionally, your team should make adjustments to the solution based on feedback after it is released. Although physical products will often depreciate over time, digital products have the potential to inherit new value through feedback and updates. Choose partners who are still investing in upgrading their systems so that solutions can continue to bring new features and new value to your business.

At Losant, we consistently add new features and functionality to our IoT platform to proactively address our clients' ever-changing business needs. Schedule a walkthrough of our platform if you’d like to learn about how the Losant Enterprise IoT Platform can accelerate your IoT projects.